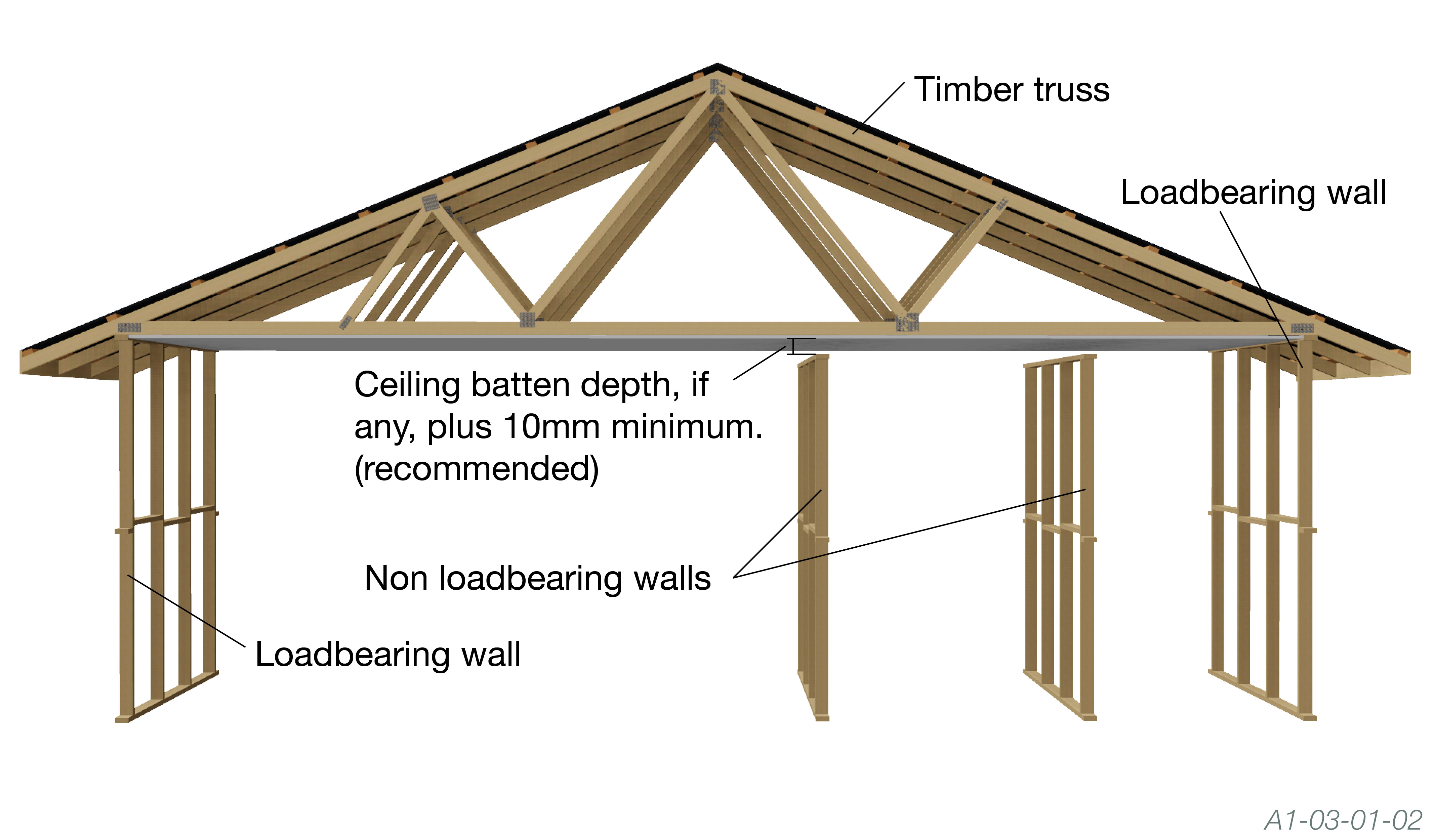

Non-loadbearing walls must comply with the requirements specified in the relevant Standards as appropriate to the material.

Non-loadbearing walls, as designated, shall not carry any truss loading and shall not be packed to touch the underside of trusses, see Figure below.

NOTE: One way to ensure non-loadbearing is to set the non-loadbearing walls at a lower level than the loadbearing walls. The recommended difference in level is the ceiling batten depth (if any) plus 10mm minimum.

Figure A1-03-01-02

Figure A1-03-01-02

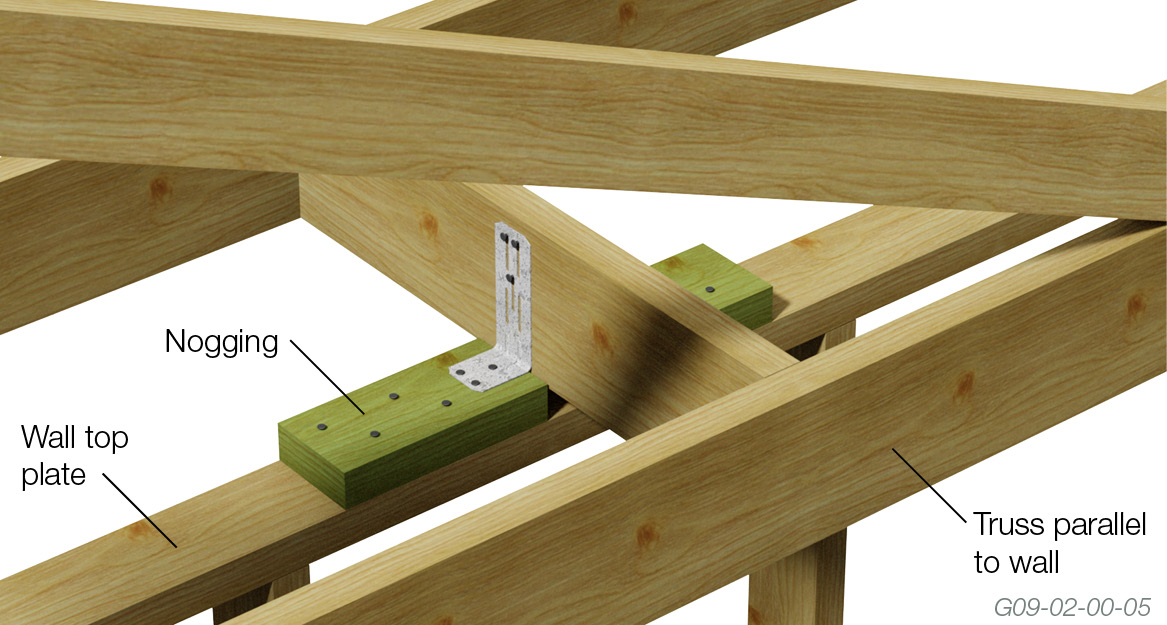

Fixing to top plates of non-loadbearing walls

The requirements for fixing of timber trusses to the top plates of non-loadbearing walls shall be in accordance with the following wall designations:

- (a) Non-bracing wall: Where a non-loadbearing wall is stable in its own right, no stabilizing fixing is required.

- (b) Bracing wall: Where a freestanding non-loadbearing wall is designated as a bracing unit in accordance with AS 1684.2 or AS 1684.3, the timber trusses shall be fixed to the top plate of the wall in such a way that the bottom chord of the truss is restrained horizontally but allows for deflection when the truss is loaded. Figure below gives an example of the fixing details.

Figure G09-02-00-05

Figure G09-02-00-05

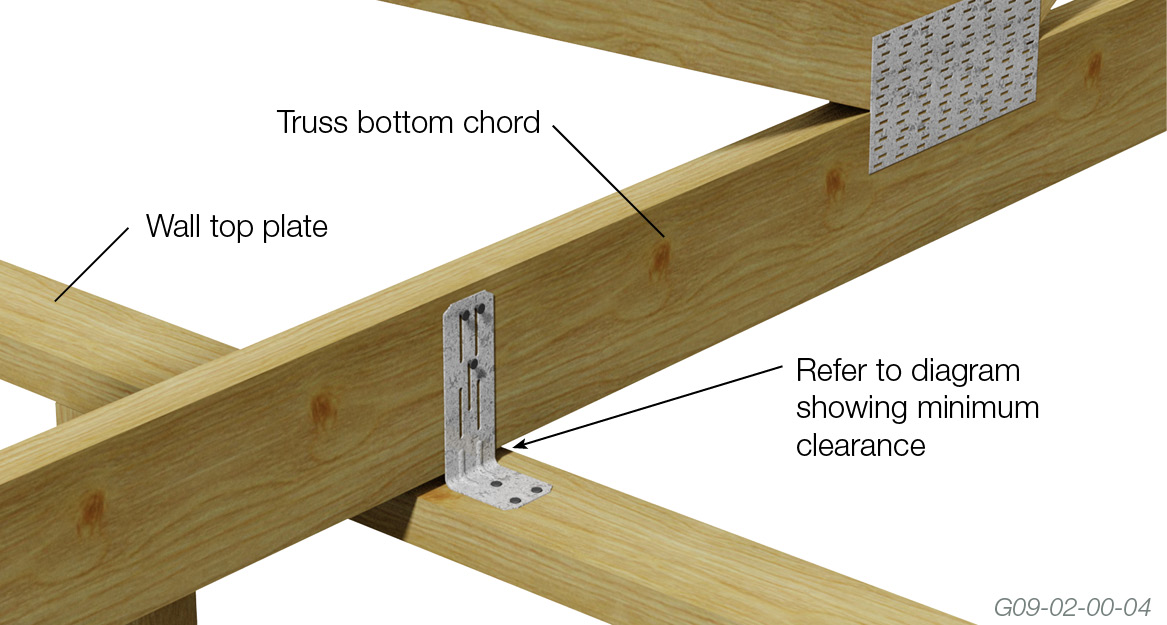

Wall is perpendicular to truss

Figure G09-02-00-04

Figure G09-02-00-04

Internal wall brackets

Internal Wall Brackets are used to connect internal non-loadbearing walls to roof trusses at maximum 1800mm centres. To enable the roof truss to deflect under loads, nails to the truss must be installed at the top of the slotted holes and not hammered home to allow a loose fit only.

Figure G09-02-00-07

Figure G09-02-00-07